LASER ALIGNMENT

Objectives of the Laser Shaft and Pulley Alignment Service

- We extend the life of your equipment

- Efficiency and quality in plant operation

- We reduce machine downtime due to breakdowns

Did you know what is the main cause of rotating machine failures?

50% of machinery problems are caused by misalignment. A misaligned machine can cost up to 30% in unscheduled downtime, spare parts, inventory and energy consumption.

Service based on ANSI/ASA Standard S2.75-2017/Part 1.

What do we avoid with Laser Alignment?

- Excessive Radial and Axial Vibration

- Bearing and Bearing Damage

- High Energy Consumption

- Deterioration of belts and pulley wear

- Electric Motor Overload

- Failure of mechanical seals

- Premature Coupling Wear

- Failure of Transmission Elements

On which machines do we intervene?

- Electric motors

- Turbomachines

- Paper machines

- Ball Mills

- Extractors

- Fans

- Cardinal Axes

- Generators

- Exhaustors

- Hydraulic Pumps

- Compressors

- Gearboxes

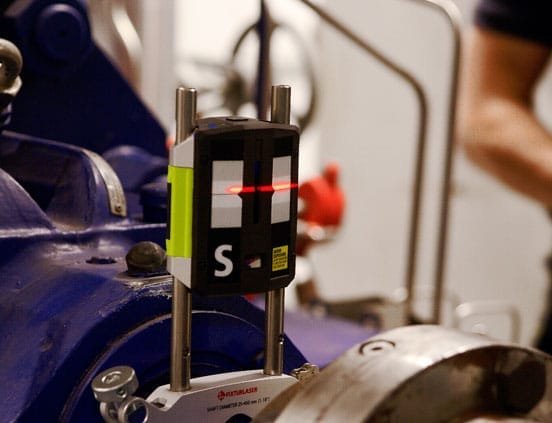

Our specialists use Acoem's FIXTURLASER alignment systems.

Fixturlaser Laser Alignment Systems

We are official distributors (Spain and Portugal). Do you want more information about our Laser Aligners? Click here

In which sectors do we specialize?

Thermosolar

Biomass

Hydraulic

Cogeneration

Wind energy

Photovoltaic

Aeronautics

Mining

cement

Automotive

Oil & gas

Metallurgy

Marine

Building

Desalination plant

Paper

Port

Pumping stations

Food and beverages

Machinery repair

In which sectors do we specialize?

Thermosolar

Biomass

Hydraulic

Cogeneration

Wind energy

Photovoltaic

Aeronautics

Mining

cement

Automotive

Oil & gas

Metallurgy

Marine

Building

Desalination plant

Paper

Port

Pumping stations

Food and beverages

Machinery repair

Where do we work?

We develop projects throughout Spain and in other countries around the world. We are in the process of growth and expansion. If you need advice about our services, please contact us.

Do you want more information about our services?

Leave us your data, make sure they are correct, we will contact you shortly.