EAGLE WIRELESS MONITORING SYSTEM

EAGLE Wireless Monitoring System

Acoem’s ONEPROD EAGLE is a semi-online wireless monitoring system for critical rotating machinery. It automatically measures vibration in three directions as well as bearing temperature.

Its measurement capabilities make EAGLE the best diagnostic solution available in the vibration analysis market. It is now possible to improve the reliability of inaccessible, mobile or isolated plant machines while reducing installation costs in harsh environments or remote locations.

Frequent monitoring of alarms

- Short periodicity for monitoring vibration velocity, acceleration and temperature.

- Raw data storage with increased periodicity and on alarm occurrence

- Battery life optimisation

4 sensors in one wireless device

- 3 vibration axes

- Bearing temperature

Variable operating conditions

- Measurements are carried out under specific conditions (speed, power, etc.).

- Easy trending and diagnostics

- Battery life optimisation

Made for diagnosis

- Analysis of phenomena up to 20 kHz

- Dynamic range +/- 50 g

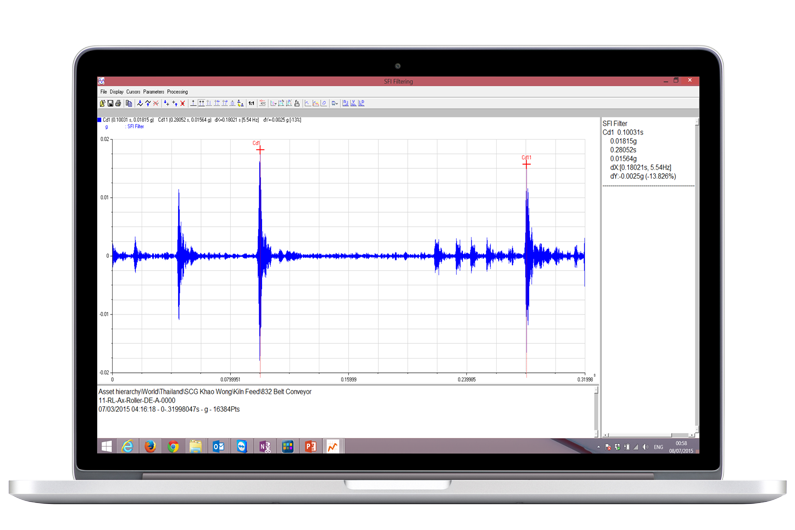

- One or more time waveform(s) and FFT per point, including the envelope FFT

- Up to 16,384 samples per time waveform (0.3 s at Fmax = 20 kHz, 0.6 s at Fmax = 10 kHz…)

Automatic communication

- Intelligent wireless protocol

- No configuration required

- Up to 100 metres between the gateway and the first node

- Up to 7 expanders between sensor and gateway

Features

Easy Implementation

EAGLE is a self-powered wireless sensor. No cable required. The wireless gateway can be installed up to 100 metres from the sensor and the range can be extended by means of wireless expanders.

The wireless transmission of vibration data to the analysis software is highly reliable: Wireless communication is established by an intelligent process, fully automatic configuration and automatic adjustment over time if required. The installation of EAGLE is quick and easy.

Rigorous Environments

The EAGLE solution has been designed to meet the requirements of the industry. Both the EAGLE sensor and the expander have been certified for use in Zone 0 (Class I, Div. I). Its stainless steel body with very low thermal expansion makes it safe to use in the harshest environments.

IP67, EAGLE is also resistant to corrosive environments. Thanks to its wireless and automatic operation, EAGLE eliminates the need for cables or manual inspections when conditions are not conducive to these tasks.

Management of machines with variable conditions

ONEPROD has applied all its experience in condition-based monitoring to EAGLE, enabling it to monitor even the most complex machines. The operating conditions (speed, power, pressure or other process data) of the machines are automatically taken into account and transmitted. The diagnostics are even more relevant and the analyses even more effective:

- Measurements can be easily translated into trends and compared over time for each of the operating conditions.

- No false alarms: thresholds are adjusted for each operating condition, providing machine fault detection capability.

Temporary Monitoring

Depending on the condition-based monitoring strategy, it is possible to monitor many machines by means of portable data collection, where vibration measurements are taken manually at scheduled intervals (e.g. every month).

EAGLE is easy to install and also easy to relocate: once a fault has been identified on a critical machine, EAGLE sensors can be relocated to monitor the machine status at much shorter intervals (e.g. every hour) in order to avoid any unforeseen failures, improve overall process availability and schedule maintenance operations only if it is really necessary.

Monitoring of critical machines

EAGLE is the best performing wireless vibration analysis system on the market. The quality of its measurements makes it ideal for monitoring any rotating machine, from 100 rpm upwards. EAGLE is not just a transducer.

This intelligent wireless device incorporates signal processing: Advanced indicators as well as the envelope FFT are calculated locally, allowing measurements to be recorded if a vibration or bearing temperature alarm occurs. The data storage frequency is automatically adjusted according to the machine status.

Data is available for detailed analysis on Acoem’s ONEPROD NEST predictive maintenance platform, which provides unique tools such as the ONEPROD Shock Finder™ filter. Maintenance operations can be scheduled before any failure occurs.

Easy Maintenance

EAGLE’s performance is optimised for long-term service with low maintenance costs. The EAGLE battery provides up to 5 years of service at rated operating conditions for a full set of diagnostic measurements per day and without the need for an external power supply or maintenance operations.

For critical machines, if an optimal monitoring strategy with frequent alarm monitoring and high quality data storage (global data, time waveform, FFT, envelope) is applied, EAGLE maintains a lifetime of 2 years. In addition, the end user can change the inexpensive standard battery on site, making it easy to replace.

Do you want more information about our products?

Ask for our Calibration Service

One of our specialists will contact you as soon as possible.