FIXTURLASER EXO LASER ALIGNER

Fixturlaser EXO Laser Aligner by Acoem

A certified smart laser alignment system for working in hazardous areas

The Fixturlaser Acoem EXO ATEX Laser Aligner is a state-of-the-art shaft alignment system designed to operate safely in ATEX zones, i.e. areas with explosion risk.

This device incorporates advanced technologies such as True Live and Vertizontal Moves™, which enable accurate and efficient shaft alignment. The patented, icon-based GuideU™ user interface makes it easy to measure, align and document every job, minimising the risk of errors.

With Acoem’s FIXTURLASER EXO, get it all in one intrinsically safe shaft alignment package.

Functions

Horizontal Alignment

It measures and helps correct misalignment, while dual sensors maintain the actual position of the shafts, even when unintentional movements are experienced during the alignment process.

Vertical Alignment

Same power and ease of use as the horizontal alignment program. The vertical alignment program is used when aligning flange-mounted machines.

Vertizontal Moves™

It allows vertical and horizontal adjustments to be made together in a single pass, saving valuable time and ensuring accuracy the first time.

Softcheck™

The Softcheck™ option helps to control lame-leg conditions. The EXO allows the user to go directly from Softcheck™ to shaft alignment measurement.

True Live

Provides live measurement values showing the exact position of the machine. The intelligent sensors adjust themselves to the current position of the machine and will always deliver values immediately.

Features

User-friendly shaft alignment in hazardous areas

True-Live

The True Live function will deliver live measurement values showing the exact position of the machine. Was the laser beam interrupted? Or was the position of the machine moved out of range of the detector? No problem, the smart sensors will resume with an updated machine position and always deliver live values.

Alignment in hazardous areas

Industry-leading EX-certified Smart Sensors

Intrinsically safe sensors for alignment

- Integrated Bluetooth for wireless communication between the display unit and smart sensors

- 30 mm digital sensor detector + line laser eliminates uneven alignment, resulting in short set-up time

- Built-in dual inclinometers for detecting backlash and obtaining angular values during measurement in horizontal alignment

- The thinnest smart sensors on the market

- Pre-assembled accessories provide a short setup time

- Instant battery check, both in on and off mode

- II 3G Ex ic op isIIC T4 Gc

EX-certified tablet

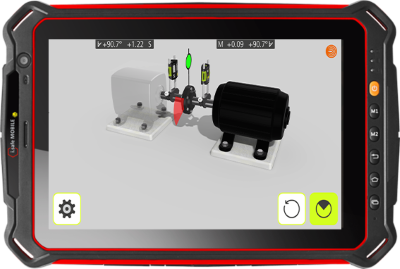

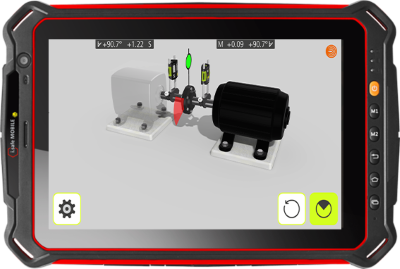

- Icon-based, colour-coded user interface a language-free user interface

- Actual values during adjustment

- Animated arrows indicating the orientation of the adjustment and the magnitude of the misalignment

- Integrated Bluetooth for wireless communication between the display unit and smart sensors

- ATEX/IECEx Zone 2 certification, including IP68 rugged tablet device

GuideU™ graphical user interface, your alignment guide

Our patented icon-based interface and colour-coded applications, GuideU, make it easy to measure, align and document your work. To minimise the risk of operator error, we developed an adaptable user interface for the Acoem FIXTURLASER EXO system.

It guides the user through the work in logical and easy-to-follow steps. It shall deliver measurement and correction values based on what the system finds during the alignment process.

To enhance the user experience, we have given the interface a game-like 3D graphical appearance that makes it easy to interpret any misalignment errors unambiguously.

Our icon-based, language-free alignment systems produce easy-to-understand measurement reports for all users.

Vertizontal Moves™

Optimise alignment with a single measurement

The VertiZontal Moves™ function shows exactly how much a misaligned machine needs to be adjusted and in which direction by adding or removing shims from the machine legs. Do not re-measure between the vertical and horizontal phases to correct for horizontal misalignment.

This industry-first feature saves time and ensures accuracy the first time. Saving time means cost savings for the maintenance department, the production department and, ultimately, savings for the entire company.

In the Box

- Tablet EX: ATEX/IECEx Zone 2 certification, including IP68 rugged tablet

- M4 mobile machine transmitter/detector with 30 mm CCD sensor and built-in Bluetooth II

- S4 stationary machine transmitter/detector with built-in 30 mm CCD sensor and Bluetooth II

- EXO V mounts, including 4-85 mm rods and 2-160 mm chains

- Carrying case – IP-65, high impact ABS

- Measuring tape EVO

- USB Flash Drive

- Manual – EXO

Do you want more information about our products?

Ask about our Laser Aligner Calibration service.

One of our specialists will contact you as soon as possible.