FIXTURLASER NXA GEOMETRY

NXA GEOMETRY

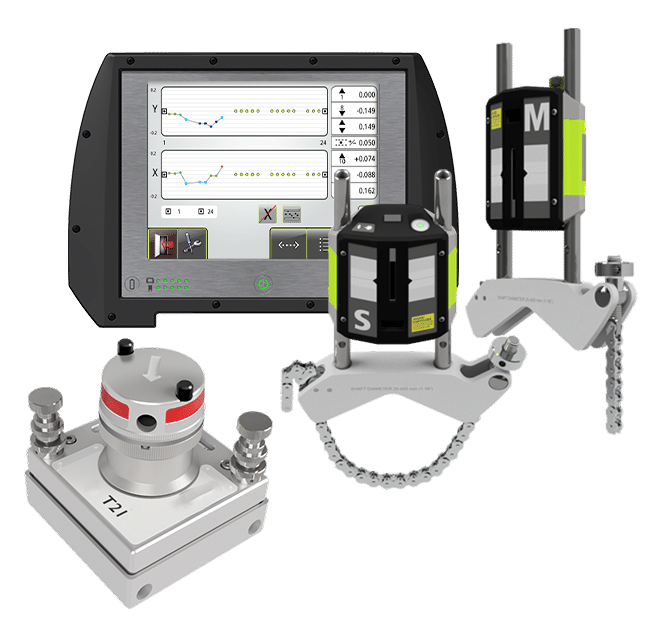

The Fixturlaser NXA Geometry is a high-precision geometric measuring system for alignment and flatness. Includes intuitive software with graphical interface for real-time measurements and micron settings. It is ideal for optimising production and reducing operating costs.

GuideU: Adaptive graphical user interface

Acoem’s laser-based geometry systems are characterised by their ease of use, thanks to an industry-leading adaptive graphical user interface.

Acoem products are easy to handle, regardless of whether you use your measuring equipment on a regular basis or only a few times a year. We also value your time, being user-friendly also means being fast!

With our systems’ graphical user interface, GuideU, you don’t have to waste time refreshing your memory or second-guessing yourself during the actual work; our user interface guides you through the entire measurement and adjustment or alignment process.

Software

The NXA Geometry includes the following software:

- Standard straightness: the measurement of e.g. machine beds, guideways or support structures.

- Straightness for full and half pitch applications: e.g. when measuring bearing journals in gearboxes, diesel engines, compressors and turbines with split housings.

- Flatness measurements, both rectangular and circular, of foundations and machine beds in machine installation.

Receptor

The NXA Geometry comes in two versions, the NXA Geometry Basic and the NXA Geometry Full respectively.

The content is the same with one exception for the NXA Geometry Full version, which also includes an additional receiver, the R2 sensor unit.

Sensor Unit R2

An optional additional R2 sensor unit can be used as a reference detector during measurement.

- 20mm 2-axis PSD detector

- Slim design

- Rechargeable lithium-ion batteries

- Lens integrated in the accessory

- Integrated address coordinates

- High precision inclinometer

- Integrated Bluetooth for wireless communication between display unit and smart sensor

- Instant battery logging in both on and off mode

Transmitters

For straightness and/or flatness measurements, you must also choose between the 4 different laser transmitters listed below:

For straightness measurements, choose between T110 or T111.

Laser transmission T110

- For straightness applications

- Rigid design for measurement stability

- Laser range up to 50 m

- Micrometric screw for adjustment of the laser transmitter in both horizontal and vertical levels

- Battery powered

Laser transmission T111

- For straightness applications

- Rigid design for measurement stability

- Laser range up to 50 m

- Micrometric screw for adjustment of the laser transmitter in both horizontal and vertical levels

- Powered by AC adapter

For straightness and flatness measurements, choose between T21 or T220.

Laser transmission T21

- For applications such as straightness, flatness and squareness

- Compact design for measurement stability

- Measuring distance up to 20 m

- Manual adjustment of the laser turret

- Battery-powered transmitter

Laser transmission T220

- For applications such as straightness, flatness and squareness

- Robust design for measurement stability and high measurement accuracy

- Measuring distance up to 50 m

- Micrometric screw for rotational adjustment of the turret

- Integrated spirit levels and micrometric screws for adjustment of the laser transmitter

- Battery-powered laser transmitter

In the Box

NXA Geometry Full R2 package with case

- Monitor

- 2 pieces of sensor/receiver R2

- 2 pcs. receiver brackets R2, cc 60 mm

- 2 pcs. rotating magnet bases for sensor holder

- Tape measure, 5m

- 2 pieces of universal angle tools

- Power supply with 2 pcs. power cables USA, EU

- Power supply with 2 USB ports, adapter plugs and USB A-micro B cable, 1,5 m

- USB memory stick

- NXA User Manual (ES)

- NXA Geometry User Manual (GB)

Accessories

Level

Level is a battery-powered two-axis measurement sensor that connects wirelessly via Bluetooth to the NXA display unit.

It can be used for:

- At the digital level

- For levelling machines or machine parts during installation

- For measuring torque on linear guides

- For measuring parallelism between machine foundations

Angular Prism

The angle prism is used for perpendicularity and parallelism measurement in conjunction with any NXA Geometry transmitter, R2 sensor and a display unit.

It can be used for:

- Parallelism between two linear guides

- Perpendicularity of flanges

- Squareness between linear guides/machine components

Do you want more information about our products?

Ask about our Laser Aligner Calibration service.

One of our specialists will contact you as soon as possible.