VIBROMETER MACHINE DEFENDER ACOEM

Acoem Advanced Vibrometer Machine Defender

Condition diagnostic application

Maximize machine life and optimize performance

The VT-300 vibrometer and the ACOEM Machine Defender application has been designed to put rotating machinery condition assessment at the fingertips of any mechanic. By simply selecting the machine components and entering the speed range, power range and mounting type.

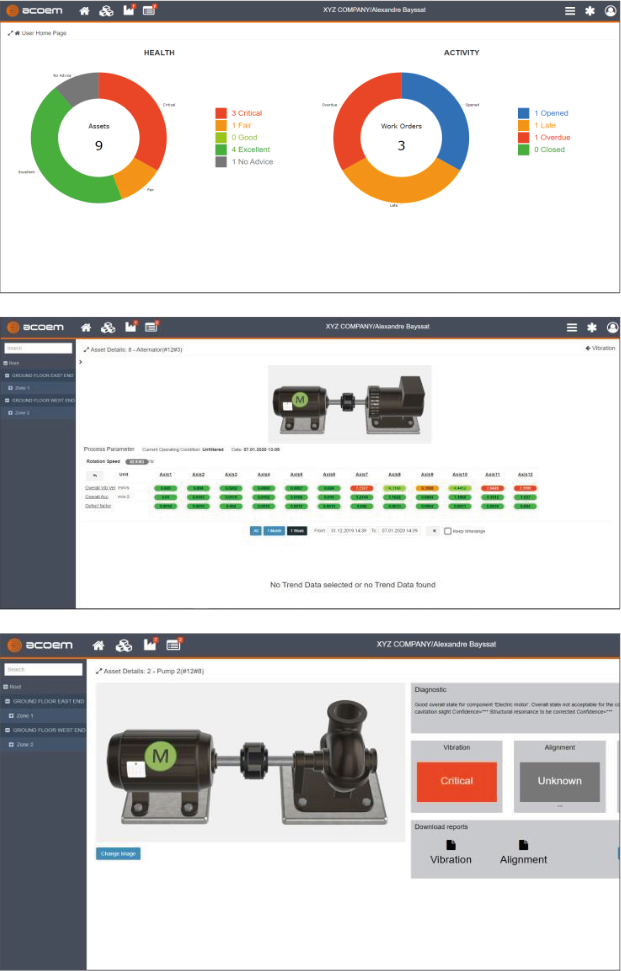

The Machine Defender advanced vibrometer tells the user if his asset is at risk and what kind of faults are likely to be present in the machine. Thanks to its 3D visual graphics-guided interfaces, any user from anywhere in the world can operate the Machine Defender application without prior training.

Features

Accurex™ Automatic Fault Diagnosis

As an integrated element within the Acoem Machine Defender system, the Accurex™ application automatically performs unparalleled diagnostics of your machinery. The patented machine diagnostics feature provides unbeatable, fast, relevant and reliable results for a wide range of machine problems, such as unbalance, misalignment, cavitation, structural resonance, bearing problems and more.

Accurex™ Automatic Fault Diagnosis

Failures generated by the patented ACOEM Accurex™ application.

The perfect partner for rotating machinery analysis services

A Vibrometer Easy to use

Thanks to our patented, color-coded, icon-based GuideUTM user interface, the operation of the Machine Defender application is intuitive and adaptable, minimizing the risk of operator error and misinterpretation of the result.

Instant field reporting functions

In the era of factory digitization, providing connectivity tools to field operators has never been more important. The Machine Defender vibrometer now completes the ecosystems of applications that enhance the capabilities of operators in the field. The PDF report can be edited and shared immediately from the mobile device right after the measurements.

Easy machine configuration in a few seconds

In just a few steps, with basic information such as Machine Type, RPM and HP, you will be ready to go.

Transmission Types

- Direct drive/ Belt drive

- Gearbox-driven coupling

- Coupling: Rigid/flexible

Transmission components

- Fans (bearings btw, pending)

- Pumps (bearings btw, pending)

- Alternators, Centrifugal compressors, Rollers, Shafts

Navigate the system with ease

The patented, color-coded, icon-based user interface simplifies the analysis of your rotating machinery. Self-guided 3D graphics create a virtual image of your machine on your tablet and eliminate potential errors. The analysis and diagnostic data is displayed in an easily digestible format and uses a traffic light system to alert you to potential failures and a percentage confidence level in your assessment, adding an additional layer of protection.

Fast and easy wireless measurements

The Machine Defender application was designed to work in perfect harmony with the Acoem wireless sensor. The patented lightweight stainless steel wireless sensor can be equipped with a high power bipolar magnet, making it suitable for curved shafts. The sensor is a triaxial wireless accelerometer, which means it can acquire synchronous measurements in the X, Y and Z directions and send them wirelessly within seconds to the mobile device.

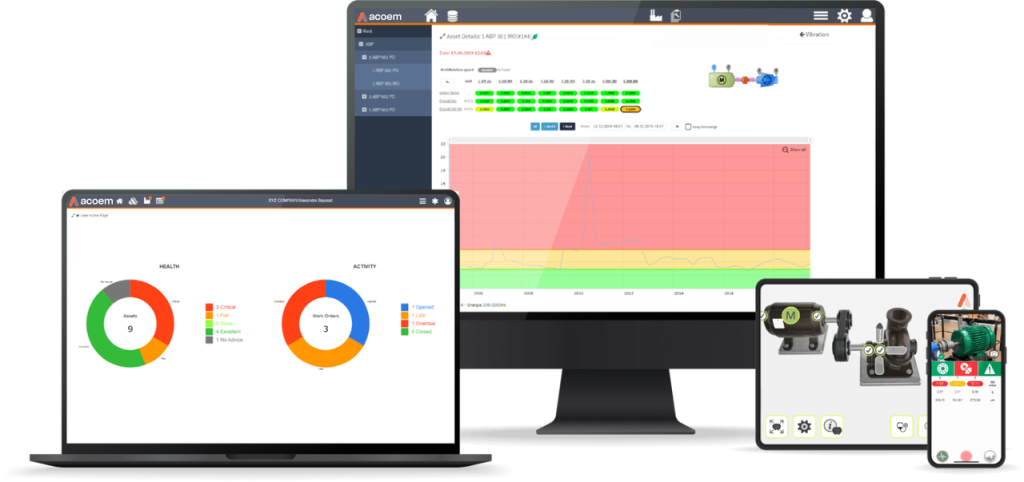

Collaborative platform in Acoem Cloud

Thanks to the Acoem Cloud platform, it is easy to get an overview of the health status of your plant’s machinery and identify performance potentials. By providing detailed access to the reporting history as well as trending potential, it facilitates the decision making process in terms of maintenance and management of measurement jobs.

Connecting to the Acoem Cloud allows you to share your data with teams across your business to take advantage of reliable performance. Operational and maintenance areas can access individual reports, machine history and trending capabilities. Vibration diagnostics of your machine will be instantly available in the field so that you can take immediate action to optimize your efficiency.

Expand your proactive maintenance capabilities

The Machine Defender vibrometer is just one solution in Acoem’s augmented mechanics ecosystem: the first truly flexible and scalable solution to combine different technologies on the same mobile platform to provide reliable and accurate predictive and proactive maintenance for industrial machinery.

In addition to the Machine Defender application, the Ecosystem currently has:

- The pre-alignment application, designed to take the complexity out of your laser alignment process, making it faster and more reliable (works with the Acoem Run-Out Probe).

- The horizontal alignment application, which offers the fastest and most accurate laser alignment capabilities on the market thanks to superior sensor technology and dedicated functions (works with the Acoem AT-200 laser alignment system).

- The Vertical alignment application, which offers the best user experience for vertical machine alignment with the same features as the Horizontal application (works with the Acoem AT-200 laser alignment system).

- Bearing Defender app, which provides quick, first-level bearing condition information based on vibration readings within seconds (works with an Acoem wireless vibration sensor)

In the Box

- 1 VT-300 wireless accelerometer sensor with Smart license.

- 1 USB power supply module with international plugs and USB cable.

- 1 high power bipolar magnet (suitable for curved shafts) with orientation key for triaxial positioning and 1 hand bag.

- 1 contact point for single-axis measurements on a small surface.

- 1 Printed safety instruction manual.

- 1 Printed calibration certificate.

Do you want more information about our products?

Ask for our Calibration Service

One of our specialists will contact you as soon as possible.