NXA ULTIMATE LASER SHAFT ALIGNER

NXA Ultimate Laser Shaft Alignment System

The name says it all!

With the NXA Ultimate cover any kind of angle you need to cover your machinery. It includes shaft alignment applications as well as geometric applications, making it, as the name suggests, the ultimate measurement tool.

Measurement methods

Horizontal Alignment

Determines and corrects the relative position of two horizontally mounted machines that are connected, such as a motor and a pump, so that the centres of rotation of the shafts are collinear.

Vertical Alignment

Determines and corrects the relative position of two vertically mounted or flanged machines that are connected, such as an engine and a pump, so that the centres of rotation of the shafts are collinear.

Rectitude

With the application, straightness can be measured in two axes. The laser beam is used as a reference and the deviation of the distance between the laser beam and the measurement object is measured at two or more positions, with the use of the receiver.

Rectangular Flatness

The rectangular flatness measurement programme uses a laser plane. as a reference. The deviation of the distance between the laser plane and the the measurement object is measured at one or more positions using the receiver.

Circular flatness

A laser plane is used as a reference in the application of circular flatness. The deviation of the distance between the laser plane and the measurement object is measured at one or more positions with the use of the receiver.

Horizontal and Vertical Machines

The NXA Ultimate is perfect for measuring horizontal alignment conditions, but its real power is in helping to correct misalignment. Dual sensors allow the NXA to maintain the actual position of the shafts, even when unwanted movements are experienced during the alignment process.

The benefit of this “true position detection” is that it allows the user to complete the alignment using Verti-Zontal™ compound motion, adjusting in both the vertical and horizontal planes without having to re-measure between movements.A Verti-Zontal™ alignment is a great time saver, as alignments can be completed in just one or two attempts.

The NXA Ultimate also comes with a number of utility programs to facilitate the alignment process. These include:

- Softcheck™ to manage lame foot conditions,

- FeetLock™ to deal with base and bolt situations,

- HotCheck™ to calculate the difference between measurements taken in a cold versus hot condition, and

- Target Values, which automatically adjusts readings to offset predetermined alignment targets based on thermal growth or dynamic motion data.

The same power and ease of use found in the horizontal alignment programme can be found in the vertical alignment programme. The vertical alignment programme is used when aligning flanged machines.

Machine train

The NXA’s machine train routine simplifies the complexity of aligning multiple units with connecting shafts. The software includes a “minimum moves” function that identifies the best reference machine to minimise the number of moves required to complete the alignment.

Spacer shaft

With spacer shafts there are two power transmission planes that must be aligned to the correct tolerances. The NXA spacer shaft program simplifies the process by showing both ends of the spacer shaft coupling with an angle/angle display. Alignment is completed using the Verti-Zontal™ movement.

Laser alignment of shafts

NXA Ultimate comes with technology-enabling features and capabilities that in many cases are industry firsts, for example:

- CCD detectors with ultra high definition resolution.

- The new Bluetooth-embedded sensor units are the most compact in the industry, yet feature a 30 mm detector surface and line lasers.

- The OmniView™ function tracks the position of both the user and the machine to display the screen from the user’s perspective, thanks to the built-in gyroscope (6-axis MEMS inertial motion sensor) in the display unit.

- Ability to track the position of the sensors in both vertical and horizontal orientation, and any tilt in between, when performing axis alignment, thanks to the built-in gyroscope in the sensor units. Therefore, you can perform shaft alignment on vertically mounted machines where a shaft rotation of 180° is not possible.

- Excellent power management: 10 hours on a single charge

Geometric Measurements

Acoem’s laser-based geometry system is characterised by its ease of use and versatility, such as:

- The graphical user interface is intuitive and animated in 3D, with colour-coded icons and symbols to guide you through the measurement and alignment process.

- Live values during measurement and simultaneous live adjustment in both vertical and horizontal orientation (X and Y values) during the adjustment process.

- The measurement results have a resolution of microns.

- Post-measurement evaluation means that you can process the saved measurement results to choose the best reference. This will result in as few corrections as possible.

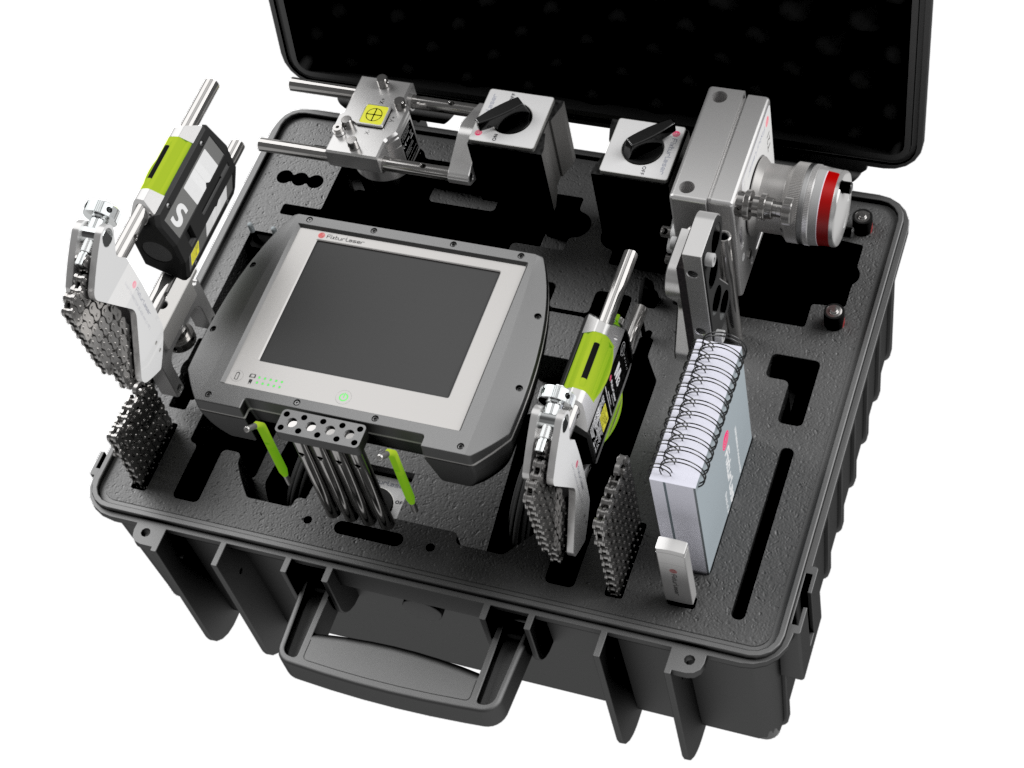

In the Box

- 6.5″ Full VGA colour display, TFT-LCD backlit, sunlight readable, with wide-angle display technology

- M3 mobile machine transmitter/detector with 30 mm CCD sensor and integrated Bluetooth II

- S3 stationary machine transmitter/detector with 30 mm CCD sensor and integrated Bluetooth II

- NXA V brackets including 4 to 150 mm rods and 2 to 470 mm chains

- Two 970 mm extension chains.

- Rod extension kit, 4-100 mm

- Two 150 mm rods

- 49 mm offset bracket

- NXA extension accessory

- Universal angle rod tools (2)

- Magnetic base for mounting on large diameter shafts

- Magnetic V-brackets (2) for applications where chain brackets do not fit

- NXA external power supply integrated in the carrying case

- T21 laser transmitter for planarity applications, incl. mounting kit

- RM Laser Receiver (Mobile Receiver) with BT-2 Bluetooth

- Carrying case: IP-65, high-impact ABS

- NXA tape measure

- USB Flash Drive

- Manuals: NXA (print & CD) and Geometry (print & CD)

- Lifetime warranty standard

Do you want more information about our products?

Ask about our Laser Aligner Calibration service.

One of our specialists will contact you as soon as possible.