Vibration Analysis: What is it and why do it?

Vibration analysis is one of the most relevant techniques in the predictive maintenance sector. It helps to assess and understand the vibration behaviour of an asset and identifies potential problems or anomalies before significant failures occur.

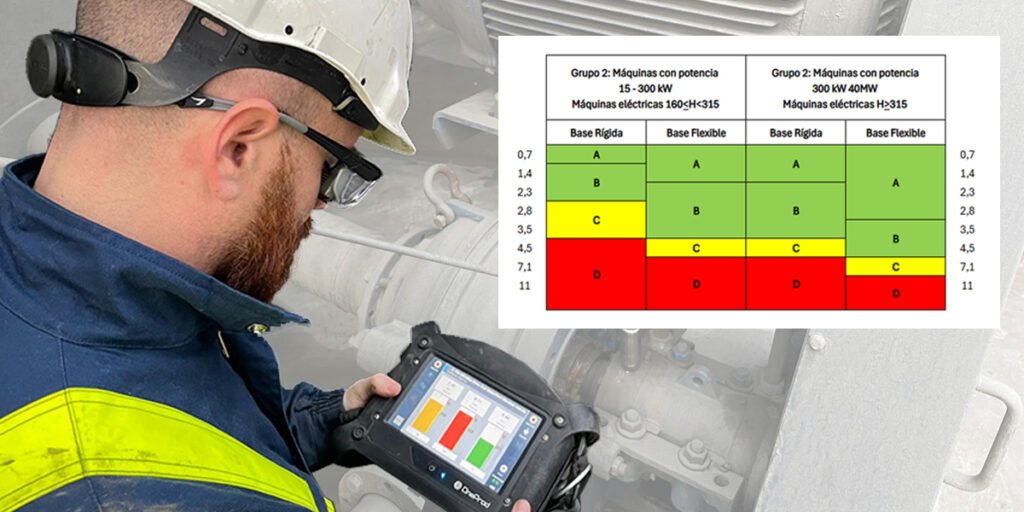

Data collection, and subsequent analysis, allows the source of the vibration to be identified and determines whether it is within acceptable limits or whether intervention is required to correct the fault.

Out-of-range vibrations may indicate imbalances, misalignments, bearing wear, gear failure, electrical problems, dynamic instability or other faults that may compromise equipment performance.

What is vibration analysis?

Vibration analysis consists of measuring and evaluating the vibrations generated by the components of a machine during its operation. The intensity, frequency and characteristics of these vibrations are detected through the use of sensors that convert the signals into data that can be analysed.

Measurement involves the decomposition of vibrations into different frequencies through techniques such as spectral analysis or impact testing, allowing the identification of characteristic patterns associated with specific machinery components; rotors, gears or bearings.

This technique relies on specialised software tools to interpret the data collected, generate reports and identify alarms.

Why is vibration analysis important?

It is important to measure vibration because this technique provides a detailed view of asset health and allows action to be taken before critical failures are caused.

This predictive maintenance technique avoids unnecessary expenditure on emergency repairs, avoids unscheduled downtime, minimising unplanned downtime, and prolongs the life of equipment.

It also improves plant safety by preventing accidents that could affect employees or the machinery itself.

Learn about our Vibration Analysis service.

Applications of vibration analysis in different sectors

Thanks to its multiple benefits, vibration analysis is presented as a versatile and essential tool in the predictive maintenance of different types of machinery and for different industrial sectors.

Our service covers a wide range of sectors (Solar Thermal, Biomass, Hydro, Wind, Photovoltaic, Aeronautics, Mining, Oil & Gas, Food, among others) and a wide variety of machinery, from electric motors to turbines.

Vibration analysis tools

The main instrument used to perform vibration analysis is the vibration collector. A specialised device designed to collect accurate vibration data from industrial machinery.

We use one of the most recognised collectors on the market, Acoem’s FALCON, a portable device with a wide range of available functions. It can be configured to perform balancing, run-up/coast-down, natural frequency identification and more.

Online monitoring systems are also used, a technological solution that allows continuous and remote real-time monitoring of machinery vibrations.

In addition, accelerometer-type sensors are used, devices that convert mechanical vibrations into electrical signals, allowing the precise measurement of machinery vibrations.

Do you want more information? Contact us

Subscribe to our newsletter

Keep up to date with all the latest news on predictive maintenance and reliability!