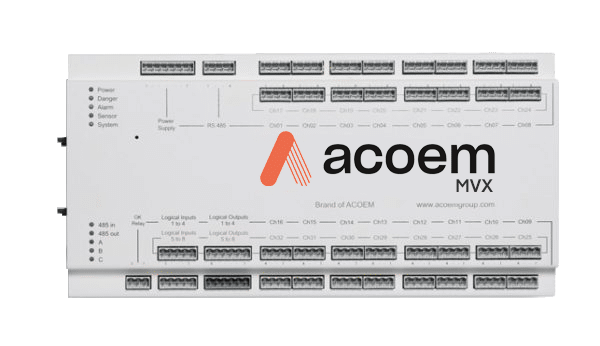

MVX REAL-TIME MONITORING SYSTEM

Real Time Monitoring System MVX

The ONEPROD MVX system is intended as a multichannel continuous monitoring solution for critical rotating equipment. Automatic real-time analysis of vibration data helps prevent failures.

The evolution of the machine’s condition is monitored with unparalleled precision, so that faults are detected at a very early stage. Welcome to predictive maintenance!

Smart

- Monitoring of variable speed and low speed machines

- Integrated intelligent algorithms

- Shock Finder™ allowing automatic detection of impacts on low speed rotating parts and gears

Multichannel

- Cost-effective configuration for a large number of measuring points: 8, 16, 24 or 32 measuring channels

- Synchronous acquisition on all channels for optimal diagnostic capabilities

- IEPE sensor, AC voltage, DC voltage, 4-20 mA, pulses,…

Features

Low speed shafts

Predictive maintenance of slow speed Predictive maintenance of is more complex to implement. Machine condition is much more difficult to assess as it requires high resolution data and advanced vibration analysis tools. Together with the ONEPROD NEST platform, the ONEPROD MVX system offers the perfect solution:

- Synchronous recording of several low-speed shaft revolutions (< 10 RPM) can be performed on 32 channels, thus improving bearing fault detection with both low and high frequency content analysis.

- Impacts from low-speed components are hidden behind the strong vibration signals and are therefore very difficult to detect. Thanks to ONEPROD Shock Finder™, an intelligent algorithm developed on real applications, its detection is automatic as it provides an early indication of low-speed component failure

- All the necessary analysis tools are available: statistical analysis, band kurtosis, intelligent filters… It is possible to analyze the trend of all post-processing indicators that help to predict the evolution of the state of a component.

Real Time Monitoring

Condition-based maintenance recommends continuous monitoring of machines at periodic intervals using various vibration indicators. ONEPROD goes one step further, as MVX offers the option to monitor indicators in real time, ensuring:

- Do not skip any monitoring event (no gaps in data acquisition).

- Responsiveness at all times: the slightest anomaly detected in real time

- Ability to detect transient or spurious events

Pre-trigger functions that allow the raw signal to be boosted just before the event.

Monitoring of complex machines

On the threshold of Industry 4.0, data logging is no longer a problem. But for machines to operate under varying process conditions, the challenge is to provide a solution capable of capturing the right data at the right time for reliable analysis and failure prediction. MVX makes it possible to monitor the most complex machines for today’s industrial processes:

- Up to 10 operating conditions can be defined using one or more process parameters;

- The data acquisition strategy, indicators and alarm thresholds are automatically adapted according to each operating status;

- Stability parameters are established to ensure that each measurement is performed under good conditions.

Do you want more information about our products?

Ask for our Calibration Service

One of our specialists will contact you as soon as possible.