NEST i4.0 FALCON & EAGLE SOFTWARE

NEST i4.0 Predictive maintenance software for use with FALCON & EAGLE

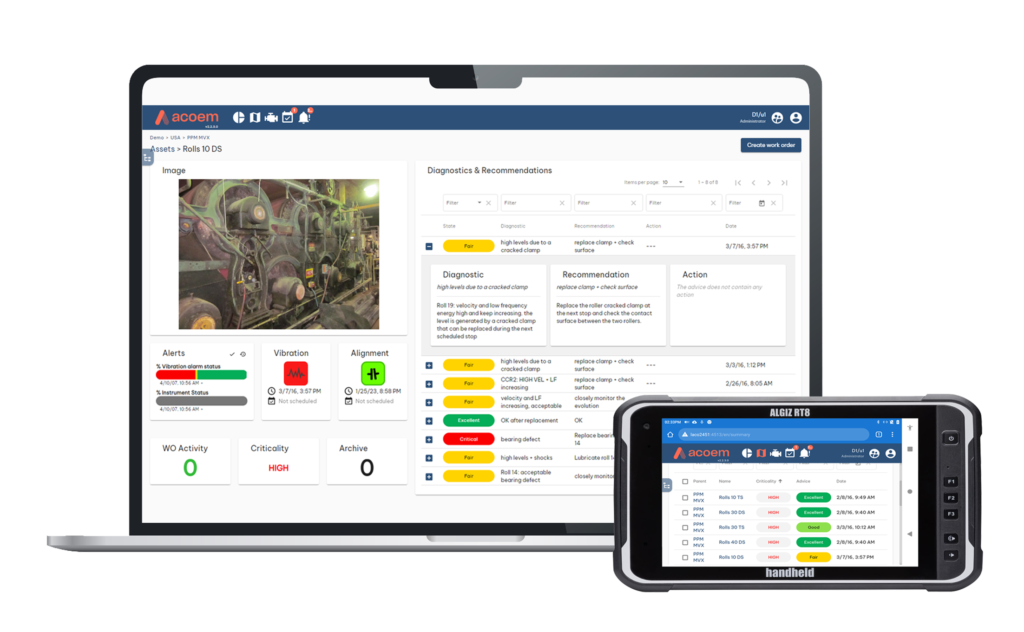

ONEPROD NEST is a software package dedicated to predictive maintenance, to determine whether maintenance actions should be planned by monitoring the condition of rotating machine.

Throughout the entire process of use, priority is given to user-friendliness: intuitive machine configuration, assistance with automated analysis, easy access to integrated automatic reports.

Based on unique expertise from more than 30 years of experience in vibration analysis, data collected from wireless sensors and analyzed by artificial intelligence systems such as Accurex ™ guide the user in their daily tasks. The flexibility of the software architecture allows the visualization of one or more production sites from a single interface in the cloud.

- Installation in less than 5 minutes

- Powerful automatic drag-and-drop configuration

- Quick and easy manual configuration from the matrix: build a machine with 30 points or more in less than one minute

- Productive diagnostics for all with new Shock Finder Index (SFx) and Harmonic Index (HMx)

- Interactive matrix: navigation from the image, compress/expand matrix for machines with many points

Features

Easy access to Big Data

Looking for conditional preventive maintenance information that is clear, concise and easily understandable? That is exactly what NEST software offers to those who maintain industrial machines in operational condition.

Intuitive and highly visual, NEST Supervision allows access to asset status for all personnel, regardless of their level of responsibility or previous experience. Access to reports is immediate from anywhere in the world via a normal Internet connection.

Intuitive machine builder

The machine configuration module allows any maintenance operator to easily configure vibration measurements. The machine is very easily described using a simple drag-and-drop tool.

By entering kinematic information (power, rotational speed, etc.) related to the machine, it is possible to automatically generate the configuration to be used with the automatic diagnostic system of the FALCON portable data collector.

For any other machine, the only additional step required is to select one of the measurement point templates supplied with the device. Hundreds of diagnostic parameters are created immediately, providing efficient and reliable monitoring of all critical assets. No vibration engineering skills are required.

Guided analysis

NEST is the most productive vibration analysis software on the market. In addition to the full range of conventional analysis tools, the user is literally guided through his analysis thanks to a set of innovative tools such as: the state matrix view, Defect Factor™ for bearings, the Shock Finder™ technology for low speed shafts, the HarmoniX™ quantifier and the Accurex™ artificial intelligence engine.

The analysis module also includes powerful functions for the most demanding users, such as display of concatenated spectra and history-based post-processing and playback functions.

The only preventive diagnostic maintenance tool you will ever need

Preventive Diagnostics

- Easy Access to Big Data

- Intuitive Machine Builder

- Guided Analysis

- Automatic Reporting

Shock Finder Index

- Easy identification and diagnosis of shocks

- Automatically scores hits on time waveforms

Bearing Defect Factor™.

- Automatically assesses the condition (health) of the roller/ball bearing

- Continuous growth during the life cycle of the bearing

- Early detection of faults

Accurex™ Automatic Machine Diagnostics

- The color of the machine (Green, Yellow, Red) corresponds to the first diagnostic level and shows the urgency of the analysis.

- The results of identified failures are pre-filled and can be modified by the user.

Open data platform

Easily connect asset health information to your operating ecosystem

- Automatically publishes all available measurement results and diagnostics from the matrix

- OPC UA and CSV standard export formats

HarmoniX™ Index

- High-resolution, full-frequency, full-frequency merged spectrum

- Automatically quantifies harmonic families in spectra

Remote Monitoring

Given the current difficult environment and the increasing focus on cost reduction, ease of access to information is crucial when deciding on the maintenance process. The NEST Dashboard allows all components to be monitored remotely from a single interface with data coming from one or several remote locations and from different sources: portable, wireless or online monitoring systems.

The NEST Dashboard is fully compliant with new IT requirements for cybersecurity, is perfect for centralized diagnostic architecture, and also allows easy access to machine status from any mobile device.

Do you want more information about our products?

Ask for our Calibration Service

One of our specialists will contact you as soon as possible.