RT-300 INTELLIGENT INDUSTRY ALIGNER

RT-300 Aligner

Machine Defender – Pre Alignment – Vertical Alignment – Horizontal Alignment

On-site machine diagnostics, plus a full precision shaft alignment tool and a connection to the cloud to save reports and look up historical data, all combined in one tool: the RT-300 is a truly unique reliability tool for the Industry 4.0 mechanic!

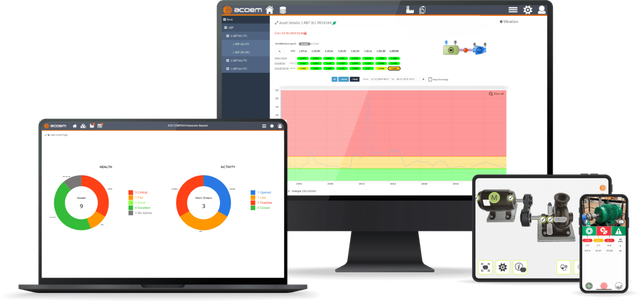

Acoem Cloud

Acoem makes the industry smarter by taking advantage of the opportunities that digitalization and mobility create for traditional industries. Data describing the condition of the machines should be collected. For this purpose, measurement results and other information provided by the RT-300 must be linked to a central collection point: Acoem Cloud.

Connection, collection and correlation enable a new kind of collaboration between people and between people and machines.

- Share secure, real-time data with technicians in the field, remote supervisors or even stakeholders on the other side of the world.

- Information is always just a click away

- Instantly share updates, maintenance job notifications, field information and asset configurations.

Machine Defender

Machine Defender’s unique Accurex™ automatic machine diagnostics system is integrated into the system. The patented machine diagnostics feature provides unsurpassed, fast, relevant and reliable results for a wide range of machine problems, such as unbalance, alignment errors, cavitation, structural resonances, bearing problems and more.

Machine Defender’s machine diagnostic function differs from all other systems.

- Patented wireless triaxial measurement

- Detects machine faults more accurately and reliably than any previous automatic diagnostic tool thanks to patented Accurex™ software.

Acoem Accelerometer VT-300

Pre Alignment

Run – Out Acoem Pre-Alignment

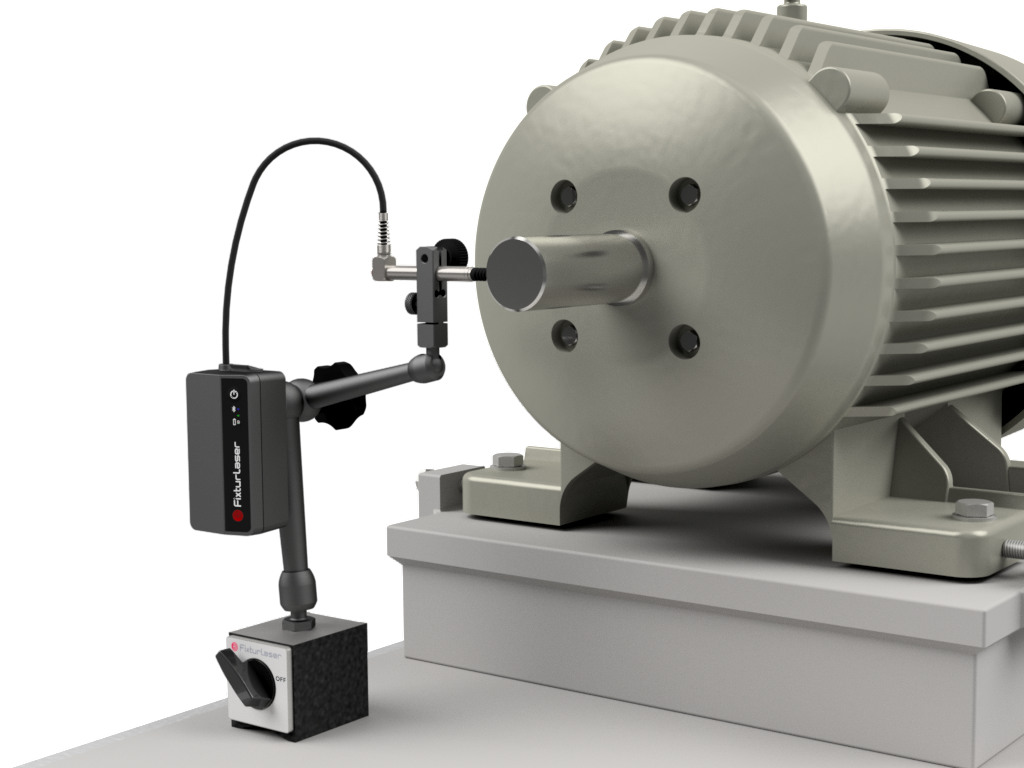

The Run-Out probe: an intelligent displacement probe for safe and reliable measurement of axial and radial deflection.

- High-precision wireless probe that measures directly at the foot of the machine.

- LVDT sensor with a measuring range of ± 2.5 mm and high accuracy (within 0.005 mm).

The Runout probe performs a multitude of applications that will improve the condition and lifetime of your machines, for example:

- Checks for axial and radial runout on flanges and shafts by measuring eccentric or bent mounting of coupling hubs and/or checking for bent shafts – runout

- Checking movements directly at the machine feet, i.e. soft foot: True SoftCheck, a pioneering function in the industry

- Checking the bearing clearances: LiftCheck

- Checking of pipe tension movements

- Thermal growth measurements on machine casings.

Axle Alignment

- IP65-certified sensor design that can withstand harsh environments

- 30 mm digital sensor detector + line laser eliminates uneven alignment and provides short setup time

- Pre-assembled accessories and small sensors provide quick setup also on machines with limited space

Real live

No guessing games, no doubt, thanks to the industry’s first use of two smart sensor technologies with visible laser beams and inclinometers that monitor both shaft positions simultaneously.

Did you interrupt the laser beam? Or move the position of the machine out of range of the detector? No problem, our intelligent sensors will resume with an updated machine position and always give you live values.

Intelligent Rotating Machine Aligner

Acoem Technology

Intuitive GuideU™ interface

GuideU™ is the next generation 3D alignment graphical user interface: our patented, customizable, icon-based, color-coded visualization system simplifies the measurement, alignment, documentation and reporting of every job.

Accurex™ automatic machine diagnostics.

Incorporating 50 years of Acoem’s experience in vibration analysis, the patented Accurex™ AI solution provides instant results for the detection of the most common defects, such as unbalance, misalignment, resonance, bearing defects, gear defects and more.

In The Box

RT-300 Package with Case

- 2 pieces of digital alignment sensors

- 2 pieces of V-brackets complete with chain

- Off-center probe

- Sensor holder (without magnetic base)

- Adjustable probe tip

- Wireless sensor (WLS)

- Magnetic base

- rod set

- 2 pieces of chains, 8 mm, 60 links (L=970 mm)

- Measuring tape 5m

- 2 pieces of universal angle tools

- Ext power cable EUR 2 m

- Extension fitting 49 mm

- Ext power cable USA 2m

- USB cable A-mini B 2m

- USB cable A-micro B 1.5m

- Power supply 5 USB 5 VDC ports

In The Box RT-300 by Acoem

Do you want more information about our products?

Ask about our Laser Aligner Calibration service.

One of our specialists will contact you as soon as possible.