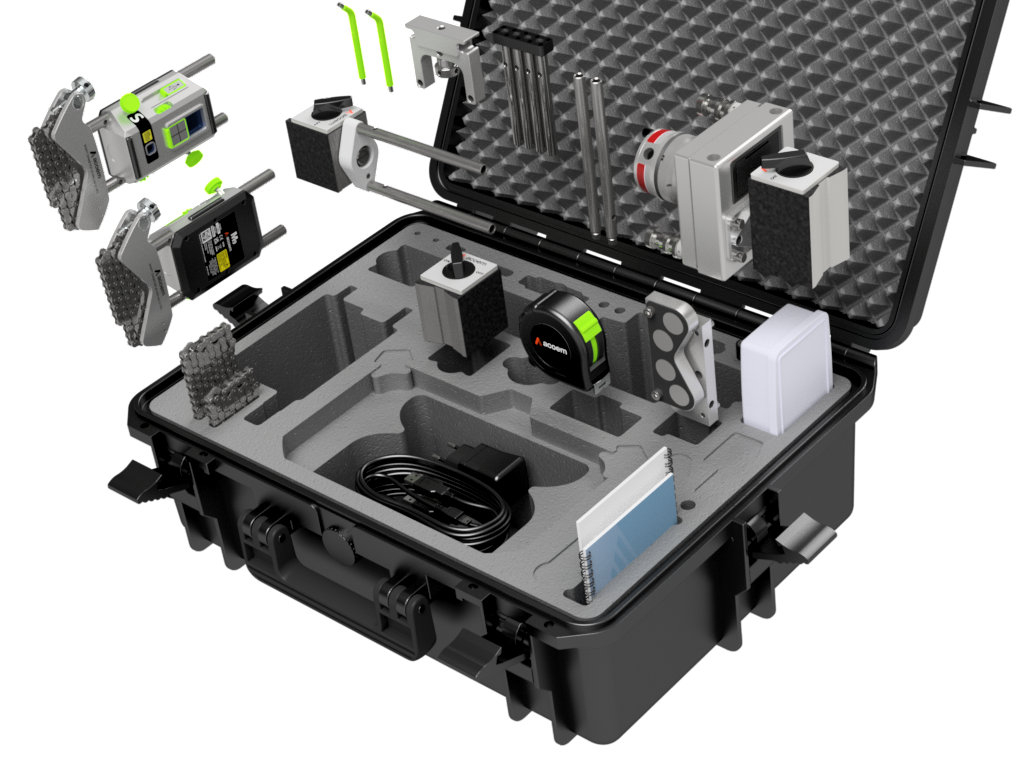

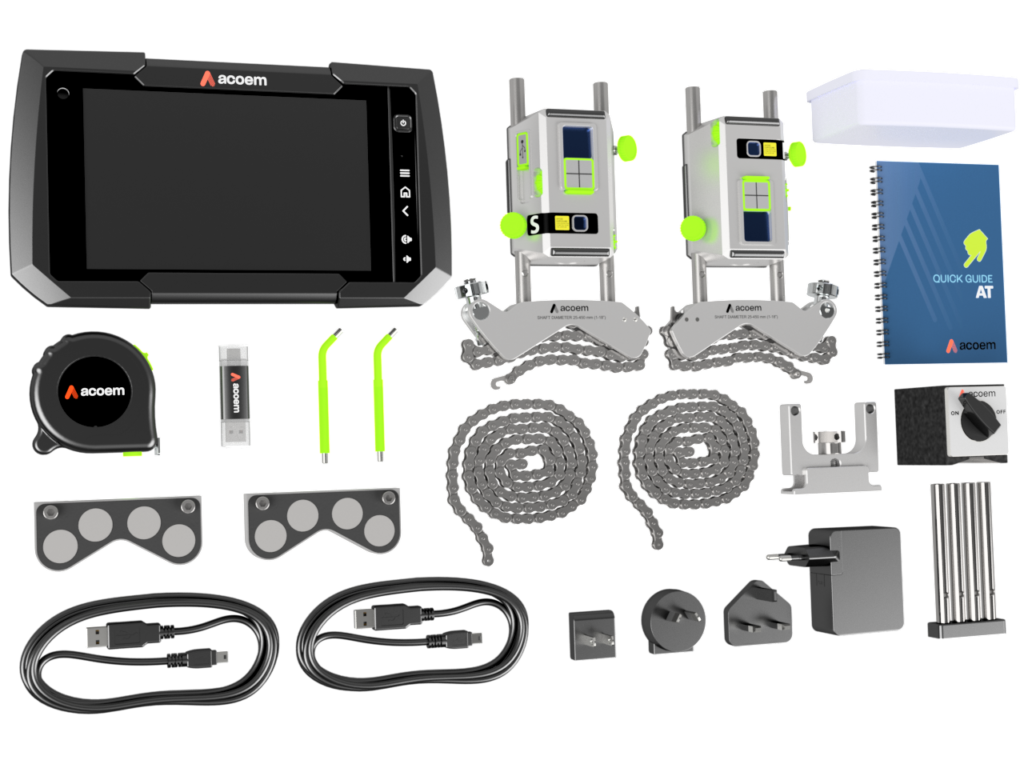

AT-400 LASER SHAFT ALIGNER

Acoem AT-400 Axis Laser Aligner

Accuracy with the AT-400 Acoem high-end dual-axis alignment system

Its Dual Sweep method captures accurate measurements during shaft rotation, ensuring optimal alignment.

Dual Multipoint offers benefits for various scenarios, capturing multiple points for accurate calculations. Cloud connectivity streamlines the exchange of reports.

Acoem’s AT-400 features robust dual-axis sensors and unmatched versatility.

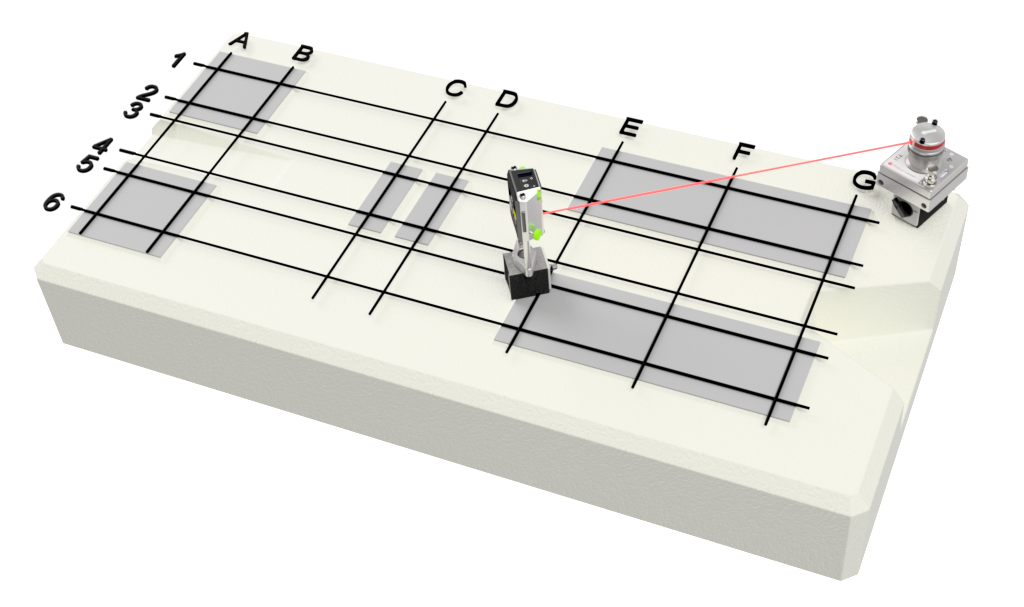

Explore various measurement programs for horizontal, vertical, flatness and lameness detection conditions.

Functions

Simultaneous Horizontal and Vertical Measurements

Sensors Acoem M9 and S9 sensors excel in measuring both dimensions at the same time, providing complete information.

High Resolution

Achieve unsurpassed accuracy with a resolution of 0.001 mmcapturing even the smallest variations for analysis.

Lightness

The 2-axis sensors are very lightweight, ensuring easy integration and mobility.

Wide Measurement Range

The Acoem M9 and S9 sensors cover up to 20 meters (65 feet) without compromising accuracy.

Design

Equipped with sliding covers, our sensors ensure product longevity and protection during storage.

Excellence in Demanding Measurements

A substantial size of 20×20 mm² and a high resolution capability of 0.001 mm make this detector ideal for demanding measurement tasks.

Functions

Simultaneous Horizontal and Vertical Measurements

The Acoem M9 and S9 sensors excel in measuring both dimensions at the same time, providing complete information.

High Resolution

Achieve unmatched accuracy with a resolution of 0.001 mm, capturing even the smallest variations for analysis.

Lightness

The 2-axis sensors are very lightweight, ensuring easy integration and mobility.

Wide Measurement Range

The Acoem M9 and S9 sensors cover up to 20 meters (65 feet) without compromising accuracy.

Design

Equipped with sliding covers, our sensors ensure product longevity and protection during storage.

Excellence in Demanding Measurements

A substantial size of 20×20 mm² and a high resolution capability of 0.001 mm make this detector ideal for demanding measurement tasks.

AT-400 Shaft Alignment System: double precision at every turn

Double precision at all times

Discover accuracy like never before with our advanced measurement methods. Engineered to perfection, these techniques redefine accuracy in industrial alignment assessments.

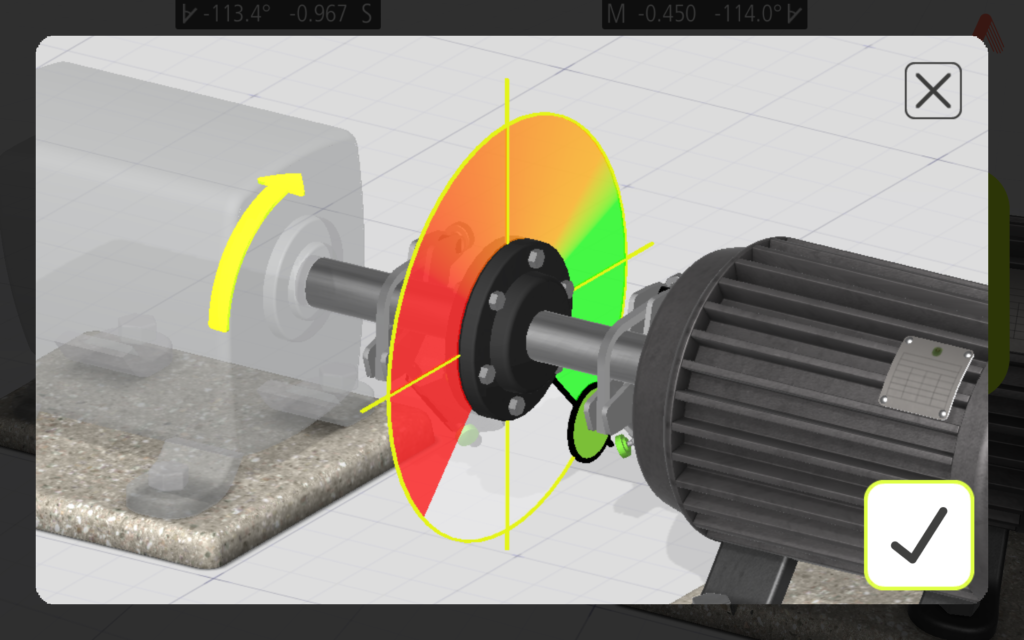

Sweep method: Automated evaluation of the alignment of the coupled machines, ensuring accuracy in each sweep. Take control by stopping data recording manually.

Sweep Express method: Effortless efficiency: data logging stops automatically when shaft rotation stops, speeding up the process.

Tripoint Method: Meticulous precision. Record three manual points during shaft rotation for detailed alignment information.

Tripoint Express Method: Automated and seamless. Experience precision alignment evaluation with automated ease.

Dual Multipoint Method: Unparalleled flexibility. Start measurements from any position, ideal for uncoupled shafts and non-rotating machinery.

Dual Multipoint Express Method: Convenience meets accuracy. Automated measurements without compromise.

Clock method: Industrial wisdom in action. Three-point, 180° rotation: a reliable technique for non-horizontal foundations and independent wells.

Advantage of Dual-Axis Alignment: Optimal Performance and Accuracy

Two-axis alignment is often the best alternative in scenarios where precision alignment in both the horizontal and vertical planes is critical to ensure optimum performance, reliability and safety of rotating machinery.

Here are some scenarios in which two-axis alignment is the preferred option:

Complex machinery: Machinery with multiple shafts, couplings and components requiring alignment in both horizontal and vertical directions benefits from two-shaft alignment. This includes systems with multiple interconnected gearboxes, pumps or rotating elements.

Critical Applications: Industries with critical applications, such as aerospace, automotive manufacturing and medical device production, often require the highest level of alignment accuracy. Two-axis alignment ensures that the machinery operates with extreme precision.

Heavy Machinery : Large, heavy machinery used in construction, mining or marine applications often requires dual shaft alignment to ensure stability and avoid misalignment-related failures.

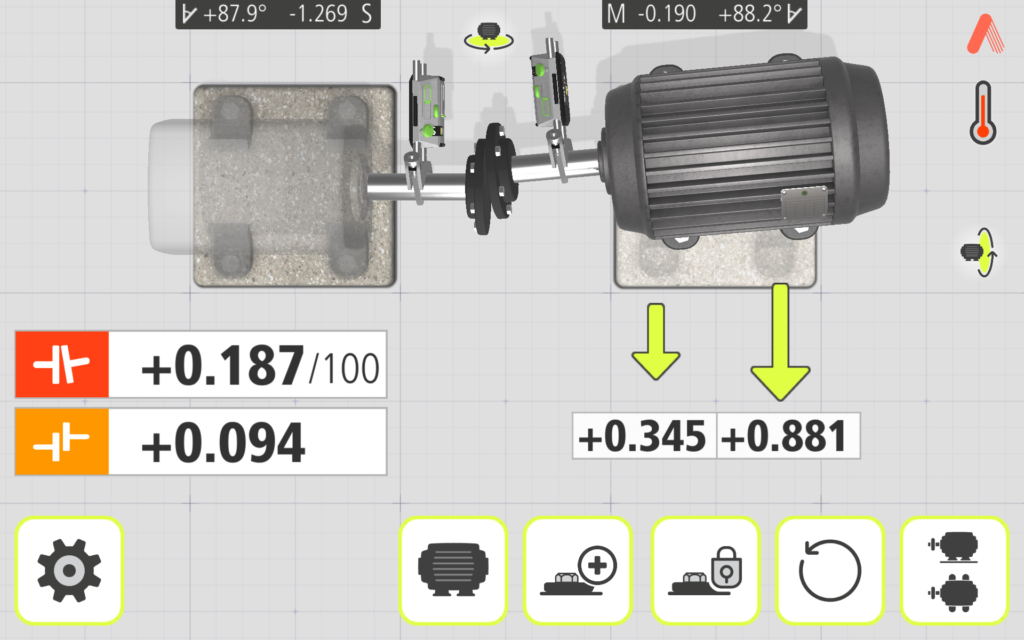

GuideU™ Interface: Revolutionizing 3D Shaft Alignment

Experience GuideU™: the innovative 3D axis alignment interface. With patented customization, intuitive icons and vivid colors; measurement, alignment and reporting become easy.

Minimize human error and uncertainty in shaft alignment through realistic graphics and animated help screens. GuideU™ Interface represents a revolutionary leap in 3D axis alignment technology. Our patented and proprietary graphical user interface redefines precision, simplicity and accuracy in the alignment process.

GuideU™ Interface features

Customization: GuideU™ offers users a patented customization system. Tailor the interface to your specific needs and preferences, ensuring a seamless alignment experience every time.

Icon-based design: Our innovative design transforms complex alignment tasks into intuitive actions. Easily navigate through the alignment process, regardless of your level of experience.

Color-coded display: Visual clarity is paramount in shaft alignment. GuideU™ employs a sophisticated color-coded display system that enhances differentiation and comprehension, promoting error-free alignment.

Realistic machine graphics: Immerse yourself in realistic machine graphics that simulate real-world conditions. Get a complete understanding of alignment requirements without the guesswork.

Animated help screens: Eliminate uncertainty with animated help screens that guide you through each step of the alignment process. Minimize the risk of human error and increase alignment accuracy.

Acoem Cloud: Seamless Connectivity to the Cloud

With the help of cloud connectivity, the Acoem AT-400 makes it easy for users to send alignment reports to the Acoem website.

This keeps the data organized and allows you to access the alignment records for checking and comparison when needed.

At the touch of a button, technicians can quickly send their alignment reports directly to the website, making their documentation process super-smooth.

Do you want more information about our products?

Ask about our Laser Aligner Calibration service.

One of our specialists will contact you as soon as possible.