ISO 20816-3: Comprehensive guide for the evaluation of vibration on rotating machinery.

ISO 20816-3 provides a normative framework for the evaluation of vibrations in rotating machinery, especially in industrial installations. This standard establishes permissible vibration limits and recommendations for their control, ensuring reliability and preventive maintenance of critical equipment.

Unlike general approaches, ISO 20816-3 takes into account both the type of machine and its operating context, adjusting the criteria for different configurations and operating conditions.

This standard establishes the general requirements for vibration assessment of various types of coupled industrial machines with a power greater than 15 kW and operating speeds between 120 r/min and 30,000 r/min, when measurements are performed on site.

Guidelines are given for applying the evaluation criteria to measurements made on both rotating and non-rotating parts under normal operating conditions. These guidelines are presented in terms of steady-state vibration values and the variations that may occur in these steady-state values.

The numerical values indicated serve as a reference, based on international experience, but should be applied taking into account the specific characteristics of each machine, as these values may not be completely adequate.

In general, the condition of a machine is evaluated by considering both shaft vibration and associated structural vibration, in addition to specific frequency components, which do not always correlate with the broadband severity values presented.

Machines to which the ISO 20816-3 standard applies

The types of machines covered by this document include:

- Steam turbines and steam generators with a capacity of 40 MW or less (see Note 1 and Note 2);

- Steam turbines and generators with power ratings above 40 MW that generally operate at speeds other than 1,500 rpm, 1,800 rpm, 3,000 r/min or 3,600 r/min (although generators are rarely included in this category) (see Note 1);

- Rotary compressors;

- Industrial gas turbines with a capacity of 3 MW or less (see Note 2);

- Turbofanes;

- Electric motors of any type, if the coupling is flexible. When a motor is rigidly coupled to a type of machine covered by any other part of ISO 20816, the motor may be evaluated in accordance with that other part or ISO 20816-3;

- Rollers and mills;

- Transporters;

- Variable speed couplings;

- Blowers or fans (see Note 3).

Note 1: Land-based steam turbines, gas turbines and generators with a capacity greater than 40 MW, operating at 1,500 rpm, 1,800 rpm, 3,000 r/min or 3,600 r/min, are covered by the requirements of ISO 20816-2. Generators in hydroelectric power plants are covered by ISO 20816-5.

Note 2: Gas turbines with an output greater than 3 MW are covered by ISO 20816-4.

Note 3: The vibration criteria presented in this document are generally only applicable to fans with power ratings greater than 300 kW or fans that are not flexibly supported. When circumstances permit, recommendations will be prepared for other types of fans, including those of lightweight sheet metal construction. Until such recommendations are available, evaluations can be agreed between the manufacturer and the customer, using the results of previous operating experience.

Machines that include a gear stage may be within the scope of this document. For acceptance testing of gearboxes, refer to ISO 20816-9.

ISO 20816-3 provides precise guidelines for vibration assessment of industrial rotating machinery, ensuring reliable monitoring of operating conditions. Specifically, it establishes acceptable vibration limits to avoid mechanical damage and maximize equipment life.

This allows operators to implement more effective predictive maintenance programs based on specific criteria for each type of machine, helping to prevent failures and optimize performance.

Machines to which the ISO 20816-3 standard does not apply

The following types of industrial machines are not covered by this document:

- Land-based gas turbines, steam turbines and generators with power ratings over 40 MW and speeds of 1,500 rpm, 1,800 rpm, 3,000 r/min or 3,600 r/min (see ISO 20816-2);

- Gas turbine sets with power ratings above 3 MW (see ISO 20816-4);

- Machine assemblies in hydroelectric power plants and pumping stations (see ISO 20816-5);

- Reciprocating machines and machines rigidly coupled to reciprocating machines (see ISO 10816-6);

- Roto-dynamic pumps and any integrated or rigidly coupled electric motor, where the impeller is mounted directly on the motor shaft or rigidly coupled (see ISO 10816-7);

- Reciprocating compressor systems (see ISO 20816-8);

- Positive displacement rotary compressors (e.g. screw compressors);

- Pumps with submersible motors; and

- Wind turbines (see ISO 10816-21).

ISO 20816-3 excludes these machines due to operational and design specificities that require different vibration evaluation criteria. For example, gas and steam turbines over 40 MW and generators operating at high speeds are subject to ISO 20816-2, which sets more stringent and specific limits for this equipment due to its critical relevance in industrial environments.

Also, reciprocating pumps and compressors are covered by other parts of the ISO standard because of their particular operation, which involves unique frequencies and vibration characteristics that are not addressed in ISO 20816-3.

These specific standards allow a more accurate and tailored evaluation for each type of equipment, which is essential to ensure reliability and efficiency in high-demand industrial environments.

Scope of application of the regulations

The requirements of this standard apply to broadband vibration measurements made in situ on shafts, bearings, bearing pedestals or machine housings under steady-state operating conditions and within the rated operating speed range.

These requirements are applicable for acceptance testing as well as for continuous or periodic operational monitoring. The evaluation criteria included in this document can be used in continuous or non-continuous monitoring situations.

Although the requirements cover machines that may include gears or bearings, they do not specifically address the diagnostic evaluation of the condition of these components. ISO 20816-3 provides guidelines for the evaluation of vibrations in industrial machines, focusing on vibrations generated by the machine assembly itself, not including vibrations transmitted to the assembly from external sources.

This standard is essential to ensure reliable monitoring of machine performance, helping operators to detect anomalies in time and avoid unexpected failures.

However, for a more in-depth evaluation of individual components, such as bearings or gears, it is necessary to resort to other standards or specific diagnostic tools.

ISO 20816-3 focuses primarily on ensuring that overall vibration levels are kept within acceptable limits, promoting the longevity and efficiency of industrial equipment.

Vibration limits

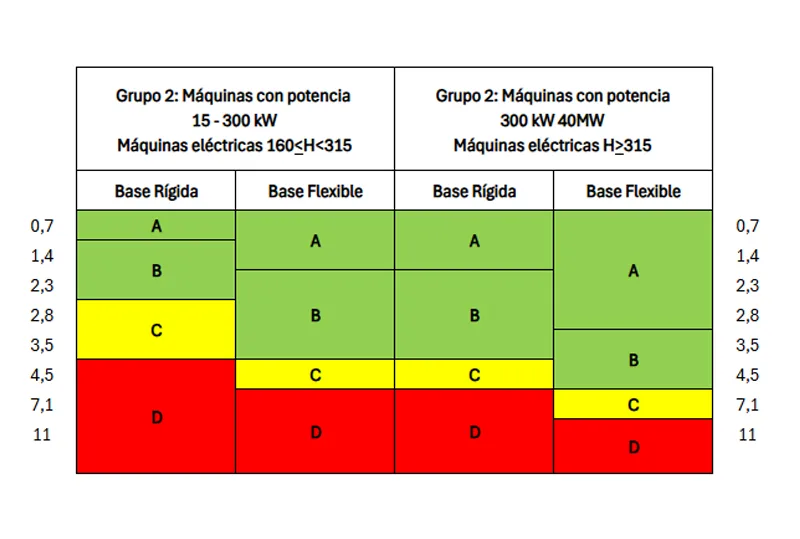

Based on this standard, the following table can be drawn up:

- For electric machines operating at 600 RPM and above

- For pumps operating at more than 1200 RPM

- For machines between 15kW and 50kW operating at more than 730 RPM

- For lower speeds, the license withdrawal criterion applies.

Zone A: The vibrations of a new machine are generally found in this zone.

Zone B: Machines with vibration levels in this zone are considered suitable for extended periods of trouble-free operation.

Zone C: Machines with vibration levels in this zone are not considered suitable for unrestricted operation for extended periods. Generally, the machine can be operated on a limited basis until corrective intervention can be made.

Zone D: Vibration levels in this zone are usually high enough to cause damage to the machine.

To ensure that your industrial equipment works efficiently and safely, DSP Analytic offers you our specialized Vibration Analysis service.

Subscribe to our newsletter

Keep up to date with all the latest news on predictive maintenance and reliability!